IEK ARMAT modular equipment is already well known to industry specialists. Devices from this line have proven themselves as reliable protective devices for electrical circuits. The quality control and verification system operating at IEK played an important role in creating the new line. How it works – we'll tell using the example of ARMAT circuit breakers.

Control throughout the entire life cycle

Using the quality control and verification system, the manufacturer monitors its product indicators at every stage of its life cycle – from the development of a new product to its market launch and subsequent operation.

"A new product will not reach the market if a series of tests to control its reliability and consumer expectations are not carried out during the pilot phase, and all possible negative aspects are not worked out," says Evgeny Ivanov, head of the Quality Service at IEK GROUP. "But when a new product is launched on the market, we already know everything about it, because we have performed all the checks prescribed by the regulatory documentation."

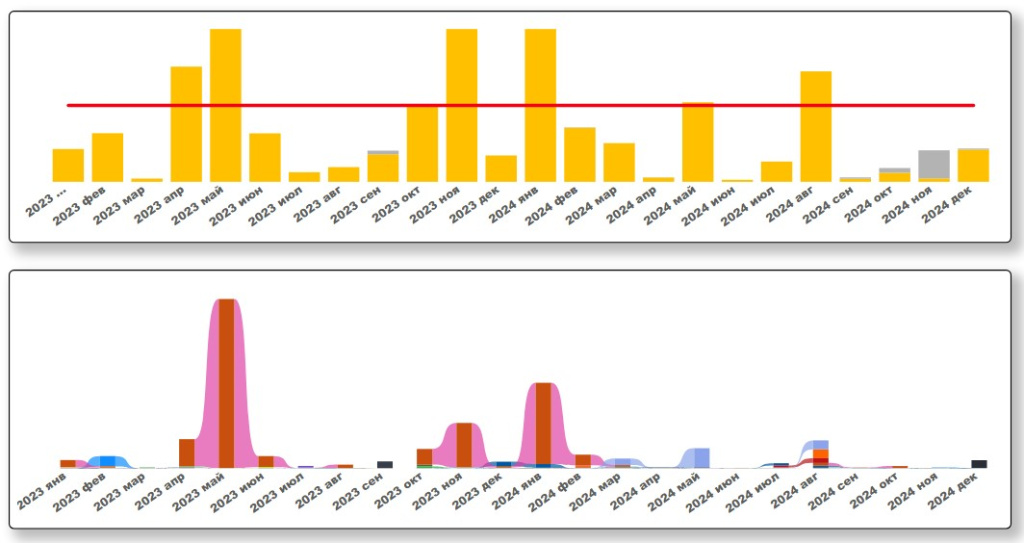

A predictive analytics system developed at IEK GROUP is also used. It includes data collection and analysis based on Power BI, coming from customers as feedback, and forecasting further developments. This makes it possible, based on the company's experience and the entire industry, to predict probable problems, including negative reactions from users of electrical products, and respond to the situation earlier than the customer pays attention to it.

The company also has a methodology for evaluating products through the eyes of the customer (G.E.P.E.S. – Group's Electrical Product Evaluation Standard, by analogy with the automotive industry). It helps identify user shortcomings that may go unnoticed during standard compliance tests. In the methodology adopted at IEK, the evaluation is conducted on 50 questions, since 2024, comparison based on consumer qualities with products from other companies has been added.

Equipment is checked at the factory...

ARMAT modular equipment is intended for industrial use, combining new technologies and the company's many years of experience. It features increased switching capacity, high mechanical and electrical endurance. The line appeared on the market in 2021 and has been expanding every year since.

ARMAT differs significantly from other IEK circuit breakers and products of other brands both in design and materials, as well as in design. Prototypes were tested by the company's laboratory specialists. "We checked the first batches not only for operating characteristics, we evaluated literally everything: packaging, completeness, appearance of the product, marking," says Alexey Alekhin, head of Testing Laboratory No. 1 at IEK GROUP.

ARMAT modular circuit breakers are produced on modern automated lines, assembly quality is carefully monitored.

"The first to check the product are the operators, purely visually. One looks, then a second, so they duplicate each other and eliminate the possibility of error. Then the assembled circuit breaker is photographed by a camera, which compares it with a reference. After this, the circuit breaker mechanism is closed with the housing, and the stage of automated checking begins," says Vladislav Krivosh, a technical-commercial representative of IEK GROUP, who monitors the production of ARMAT circuit breakers at the factory.

Machines calibrate the thermal release, check insulation strength, circuit integrity, screw clamp, free-tripping mechanism, and also automatically reject substandard products.

In addition, right there at the factory, the ultimate switching capacity of the circuit breaker is checked. For this purpose, overcurrents – 6000 and 10,000 A – are passed through it. It is worth noting that the ARMAT manufacturer has the necessary equipment for such tests in its arsenal, while far from every independent laboratory can afford it.

After a batch of circuit breakers comes off the assembly line, strength tests for them do not end. First, the devices undergo acceptance tests to control product compliance with standard requirements, then periodic tests to confirm product quality and stability of the technological process. They are conducted by the factory's technical control department under the supervision of the company's technical representative.

...and then tested in the company's laboratory

Finally, ARMAT circuit breakers are shipped from the factory. But they will not reach the customer until they undergo another suitability assessment procedure.

"A batch arrives at the warehouse with a 'blocked' status. It is not shipped to customers until we publish the result of the incoming inspection," explains Alexey Alekhin.

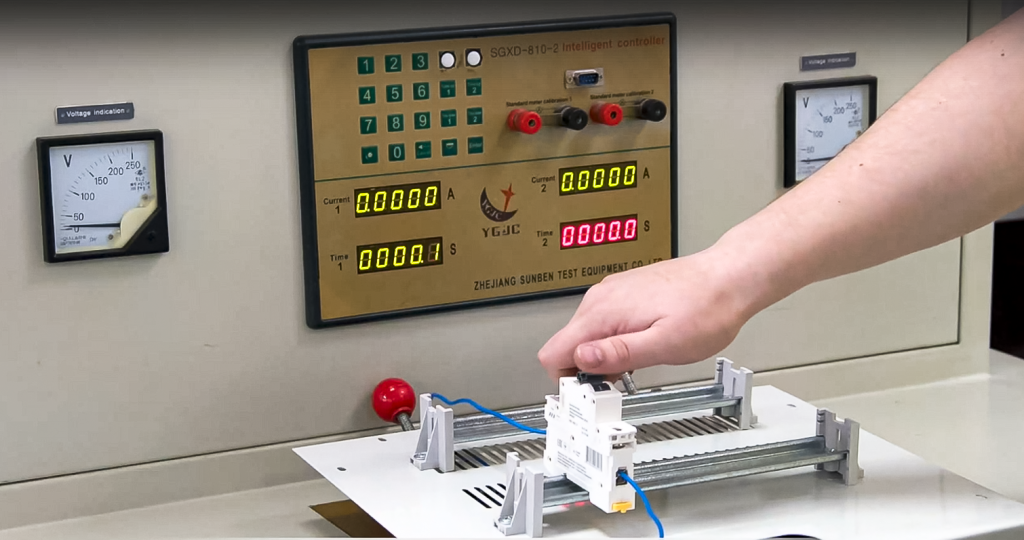

Batch quality is tested on a sample. First of all, the operating characteristics of the circuit breakers are checked – mechanical operation and thermal release.

Non-tripping test at 1.13 In.

The thermal release is first tested by applying a non-tripping current of 1.13 In. According to GOST IEC 60898-1-2020

Other indicators are also checked. Specialists evaluate the reliability of screw terminals for external conductors, temperature rise, power losses, insulation resistance, dielectric strength of insulation, resistance to abnormal heat and fire, and the composition of the circuit breaker materials.

Tightening with a torque of 5 N·m.

"The laboratory has a unique stand on which six circuit breakers can be placed for testing at once, thereby increasing throughput," continues Alexey Alekhin.

A very important stage of testing is the test for resistance to heat and fire. According to standards, during glow-wire tests, parts of the housing and mechanisms in contact with live parts may ignite but must self-extinguish within 30 seconds after contact with the wire ceases. It is also important that the plastic does not form burning droplets capable of igniting tissue paper placed under the test sample.

IEK GROUP laboratory specialists also test ARMAT circuit breakers for ultimate switching endurance. The electrical endurance of the circuit breaker is 10,000 cycles, which is 2.5 times more than required by test standards.

Alexey Alekhin admits – he has had to reject batches of ARMAT "modulars". But the defects were rather cosmetic, not affecting the operability of the circuit breakers. For example, the marking on the housing was printed crookedly. An insignificant detail, but IEK GROUP specialists pay attention even to such trifles.

Checking insulation resistance of a modular circuit breaker with a megohmmeter.

"We pay a lot of attention to ensuring there is no defect in the production process," says Evgeny Ivanov. "We do this, among other things, to protect the customer."

The holding's products are certified according to STO Gazprom

The company's successful experience can be extended to other enterprises in the industry, especially since IEK requires high product quality from numerous suppliers, introducing its requirements to them and strictly controlling their fulfillment.

REFERENCE:

The ARMAT range includes devices with tripping characteristics B, C, D, Z, K, L, rated currents from 0.5 to 100 A and rated breaking capacity from 6 to 10 kA.

They are distinguished by increased endurance – withstand up to 10,000 switching cycles under load. They have a modernized free-tripping mechanism, which allows faster circuit breaking. Eight rivets make the design more reliable. The tightening torque of screw connections is increased to 5 N·m, ensuring quality contact connection and reduced losses at the transition resistance point.

ARMAT circuit breakers feature an improved arc chute, ensuring increased reliability. They have certificates for household and industrial applications (circuit breakers with time-current characteristics Z, K, L), suitable for use at high short-circuit currents.

In 2023, ARMAT DC circuit breakers in 3P and 4P designs appeared. That same year, a hot-swap module was added to the assortment, allowing standard ARMAT, KARAT circuit breakers to be used as plug-in devices.

In 2024, the company released M10H circuit breakers for 80 and 100 A currents with double contact break for faster and more effective arc quenching, circuit breakers for ventilation and fire extinguishing systems, devices for protecting three-phase motors. A remote handle for remote control of modular equipment also appeared.