"Complies with GOST" — such marking can be seen on IEK GROUP products. This means it is created in accordance with state quality requirements. However, IEK not only manufactures goods according to GOSTs but also participates in their development.

What is GOST?

GOST is a document that establishes uniform requirements for products, works, processes, and services. It protects consumer rights, guaranteeing the quality and safety of goods manufactured in accordance with it, ensures compatibility and interchangeability of products. Manufacturers, with the help of GOSTs, understand what a quality product should be like.

Who develops GOSTs?

State standards, as well as other standardization documents, are approved by the Federal Agency for Technical Regulation and Metrology (Rosstandart), and are developed by Technical Committees (TC) on standardization.

Who is part of the technical committees?

Specialists who are authorized representatives of interested enterprises and organizations. IEK GROUP is a member of four committees creating standards for the electrical industry. These are TC No. 331 "Low-voltage switching apparatus and complex distribution, protection, control, and signaling devices", No. 332 "Lighting products, artificial lighting", No. 337 "Electrical installations of buildings" and No. 420 "Basic supporting structures, printed circuit boards, assembly and mounting of electronic modules".

Why should a business engage in GOST development?

Chief Expert of the IEK GROUP Quality Service Nikolay Dushkin, authorized representative of IEK GROUP in technical committees: "As a manufacturing company, we care about our customers and partners. It is in our interest to have standards for products and follow them. By purchasing goods manufactured in accordance with GOST, buyers can be confident in their quality and reliability, and manufacturers, by applying GOST, demonstrate their integrity."

How is the work of technical committees structured?

Members of technical committees submit proposals for the development of standardization documents, contribute ideas for amendments to existing standards and draft new ones, participate in discussions and vote on all matters of the TC's activities. At IEK GROUP, this work involves relevant specialists from the company's divisions — the Technical Regulation Service (TRS), R&D, and others.

Leading Engineer of the Conformity Assessment Department of the IEK GROUP Technical Department Dmitry Kondrashkin: "The committee considers all received proposals and comments. A summary of feedback is prepared, a meeting is convened to review them, where the authors of amendments can explain their position in more detail. Based on the meeting results, a final summary of feedback is approved, on the basis of which the final version of the GOST is issued."

What are the results of IEK GROUP's work in technical committees?

IEK GROUP participates in the publication of all standards issued by the TCs of which it is a member. Of particular importance to it are those concerning current problems of electrical devices and new directions. Here are some examples of the company's activities in the committees:

― GOST IEC

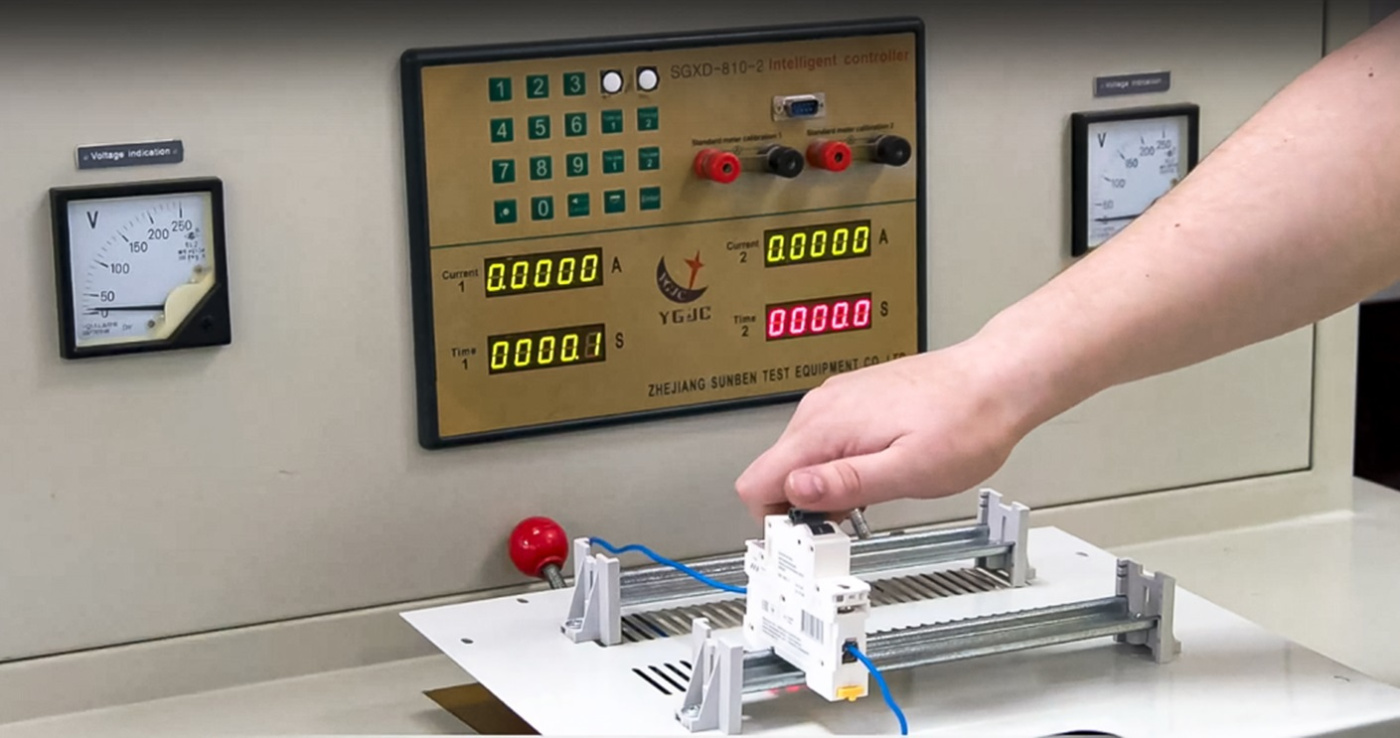

Nikolay Dushkin: "There were many complaints about the device used to test the electromagnetic release: because of it, the breaker tripped earlier than necessary. We proposed to introduce an amendment — to use for operability control only devices that supply the release with a current of practically sinusoidal waveform, which will help avoid false results."

― The release of "Amendment No. 6 to SP 256.1325800.2016 Electrical installations of residential and public buildings. Design and installation rules", in the development of which IEK GROUP engineers also participated, updated requirements for the use of AFDDs to improve fire safety.

― IEK GROUP received approval from TC331 to introduce an amendment to GOST IEC

― Two standards of the 61238 series "Cable lugs for electrical purposes — Mechanical crimping", proposed by IEK GROUP, have passed all approvals and are being prepared for publication.

What else does IEK GROUP gain from working in technical committees?

This is an additional channel for receiving feedback from consumers: not only organizations but also individuals have the right to apply to a technical committee. Sometimes, like the author of the SamElectric.ru blog Alexander Yaroshenko, citizens do this through IEK GROUP. The result of the joint work — introducing an amendment to GOST 61008-1—2020 "Residual current operated circuit-breakers without integral overcurrent protection for household and similar uses (RCCBs)" (clarification of an incorrect translation from the original language).

Furthermore, it provides an opportunity at the stage of adopting standardization documents to filter out unscrupulous manufacturers or potentially unsafe products. For example, at one of the TC337 meetings, a proposal to use AFDDs with signaling but without tripping was rejected — the risk of such a device igniting was considered too great by the technical committee members.

Working in committees helps to be aware of what product requirements will come into force in the future and to prepare for them in advance. For example, even now in product development, materials from the 62722 and 62717 series standards for luminaires with LED modules can be used.

Manufacturers get the opportunity to convey their position externally, thus influencing the development of the electrical industry in the interests of manufacturers and consumers. Also, working in TCs is an excellent school for company employees; it allows them to accumulate technical knowledge and, consequently, improve the company's products.

How is IEK GROUP's work in technical committees structured this year?

IEK GROUP is actively participating in the development by technical committees of interstate (GOST), national (GOST R), and preliminary national standards (PNST) for certain areas of the electrical industry to ensure its import independence.

Also, currently, as part of the Technical Committees, the company is actively participating in the formation of the national standardization plan for