When laying cable lines, it is important to correctly choose the type of protective coating for the cable tray depending on the possible impact of the environment. In the IEK assortment, there are many such coatings: steel, galvanized in different ways, stainless steel, powder coating in RAL palette colors, etc. Why such variety and how not to get confused in the choice?

In this article, we will talk about the features of each coating and explain for which operating conditions it is intended.

Sacrificial coatings

These are coatings that react with the atmosphere, thereby preventing metal oxidation. Most often, zinc is used for such coatings. The resistance of the metal product to corrosion will then be determined by the thickness of the protective layer: the thicker it is, the better the resistance to environmental impact.

Steel, galvanized by the Sendzimir method

Features. The steel sheet is treated with chemicals, oxides and oils are removed, then annealed in a furnace and rolled in a bath with molten zinc. After that, excess zinc is removed with special air knives to make the coating uniform.

Where is it used? In premises with low humidity and contamination: in office and shopping centers, sports halls, small heated warehouses, and other premises without temperature and humidity fluctuations.

Where should it not be used? With Sendzimir galvanizing, the protective coating is very thin: only

Trays galvanized by the electrolytic method or by the Sendzimir method are suitable for offices, shopping centers, and sports halls.

Electrolytically galvanized steel

Features. Well-cleaned and degreased steel parts are immersed in a zinc-containing electrolyte, where under the influence of electric current, zinc molecules "stick" to the surface of the product. As a result, a uniform and sufficiently strong coating is formed on the metal, protecting the steel from corrosion.

Where are they used? Since usually the thickness of the protective layer with this galvanizing method is not great, their scope of application is similar to that of trays galvanized by the Sendzimir method.

Hot-dip galvanizing

Features. Ready and cleaned steel parts are immersed in molten zinc. As a result, a zinc layer is formed on the metal, protecting it from corrosion. After that, the products are treated with phosphates, which increases their wear resistance and strength.

Where are they used? Due to the greater thickness of the protective layer, hot-dip galvanized steel resists corrosion better. Cable trays made of it can be used in unheated premises, production workshops, for outdoor installation, as well as in areas with industrial pollution: on production sites, in car tunnels, and on overpasses.

Where should they not be used? It is not recommended to use hot-dip galvanized products in coastal areas with high chloride concentration and risk of sea water splash, as well as in productions with strong corrosive activity of the atmosphere (exposure to acid, alkali vapors and splashes, aggressive organic compounds). Use is also limited in food and pharmaceutical productions.

Hot-dip galvanized steel resists corrosion excellently and can be used on production sites.

Thermal diffusion galvanizing

Features. The coating is applied to ready steel products. They are thoroughly cleaned and dried, then placed in a special container, where zinc powder is later added. Then the temperature inside the container is raised to a certain value and the products are held from one to several hours depending on the requirements for coating thickness.

Where are they used? The coating thickness and, consequently, the application area of the finished trays will depend on the temperature and holding time of the trays in the container. Therefore, be sure to clarify the corrosion resistance class of the finished products.

Corrosion-resistant materials

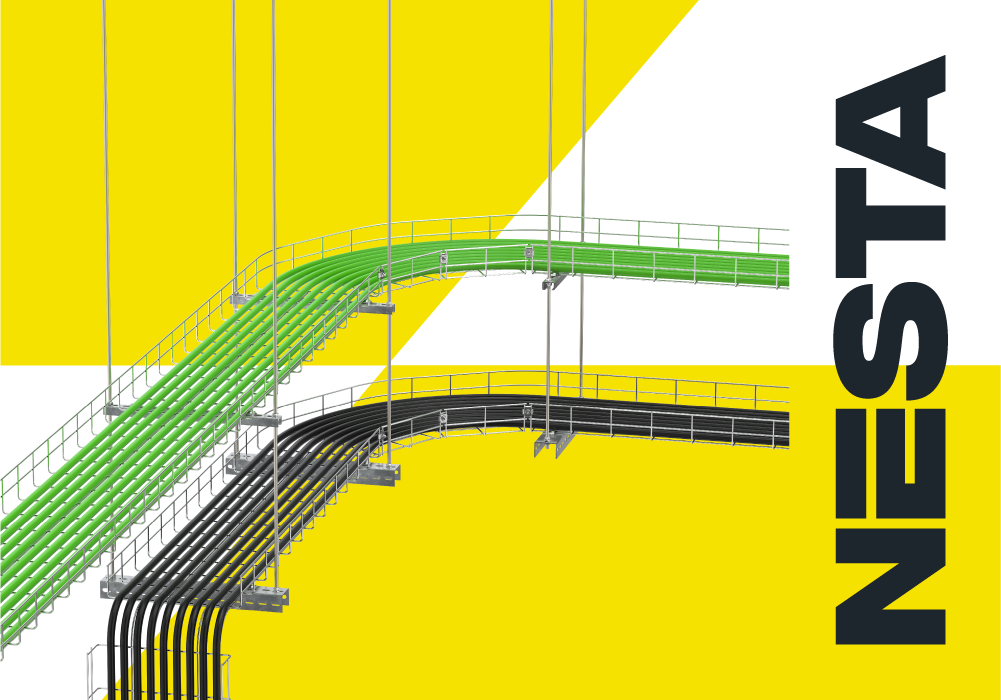

Besides protective coatings, there is a whole class of materials resistant to corrosion due to their chemical composition. The most famous of them are stainless steels. In the NESTA IEK tray assortment, there are products made of this material.

Stainless steel AISI 304

Features. Steel grade AISI 304 contains about

Where are they used? Trays made of AISI 304 stainless steel are actively used at agro-industrial complex enterprises, in the food and pharmaceutical industries, in mineral fertilizer production, and in the chemical sector.

Where should they not be used? Products made of AISI 304 stainless steel are not recommended for installation on offshore platforms and in coastal areas with possible direct contact with sea water, as well as at enterprises with very high corrosive activity of the atmosphere (high concentration of acid and alkali vapors).

Trays made of stainless steel are actively used in the agro-industrial complex.

Decorative coatings — powder coating

This type of coating is used exclusively for aesthetic purposes. Coloring is possible in any shade of the RAL palette and is done to order. It is applied to trays made of electrolytically galvanized steel or steel galvanized by the Sendzimir method.

The assortment of NESTA metal wire mesh trays includes versions for various applications and budgets. All products are made from high-quality Russian raw materials on high-tech automated equipment. No matter which version you choose, you get sturdy trays, convenient for installation and safe in operation!