At large enterprises in mining, metalworking, and construction industries, presses and crushing and screening equipment are used in a single technological chain. Failure of one unit can stop the entire line and cause losses for the enterprise. Therefore, the key task becomes ensuring uninterrupted equipment operation and minimizing downtime risks.

In the article, we will tell how a soft starter (SS) helps with this task and share a case study of using the ONI SFC SS in conjunction with press equipment.

Market situation

According to expert observations, in Russia, in the segments of industrial press and crushing and screening equipment (CSE), steady growth and expansion of the product range are observed. This is facilitated by state programs supporting industrial sectors and the modernization of outdated equipment.

Press equipment includes several segments: hydraulic presses, presses for rubber and plastics, and forging and press machines. Hydraulic presses occupy up to 50% of the market volume, with equipment from Russian manufacturers predominating in the overall vendor list.

The CSE market in 2024 exceeded 50 billion rubles, showing growth of about 6% compared to the previous year. Here, products of large Chinese and Asian brands dominate, although Russian manufacturers are confidently increasing their presence. For consumers, the most important advantages are equipment reliability, parts availability, and quick technical service.

Thus, the Russian markets of press mechanisms and crushing and screening equipment have good growth potential and attractiveness for investors. Further strengthening of the ruble, state support, and active investments create prerequisites for the sustainable development of these industries in the coming years.

VFDs in press equipment and CSE industries

ONI K750 frequency converters work excellently in harsh conditions such as crushers, mixers, and presses.

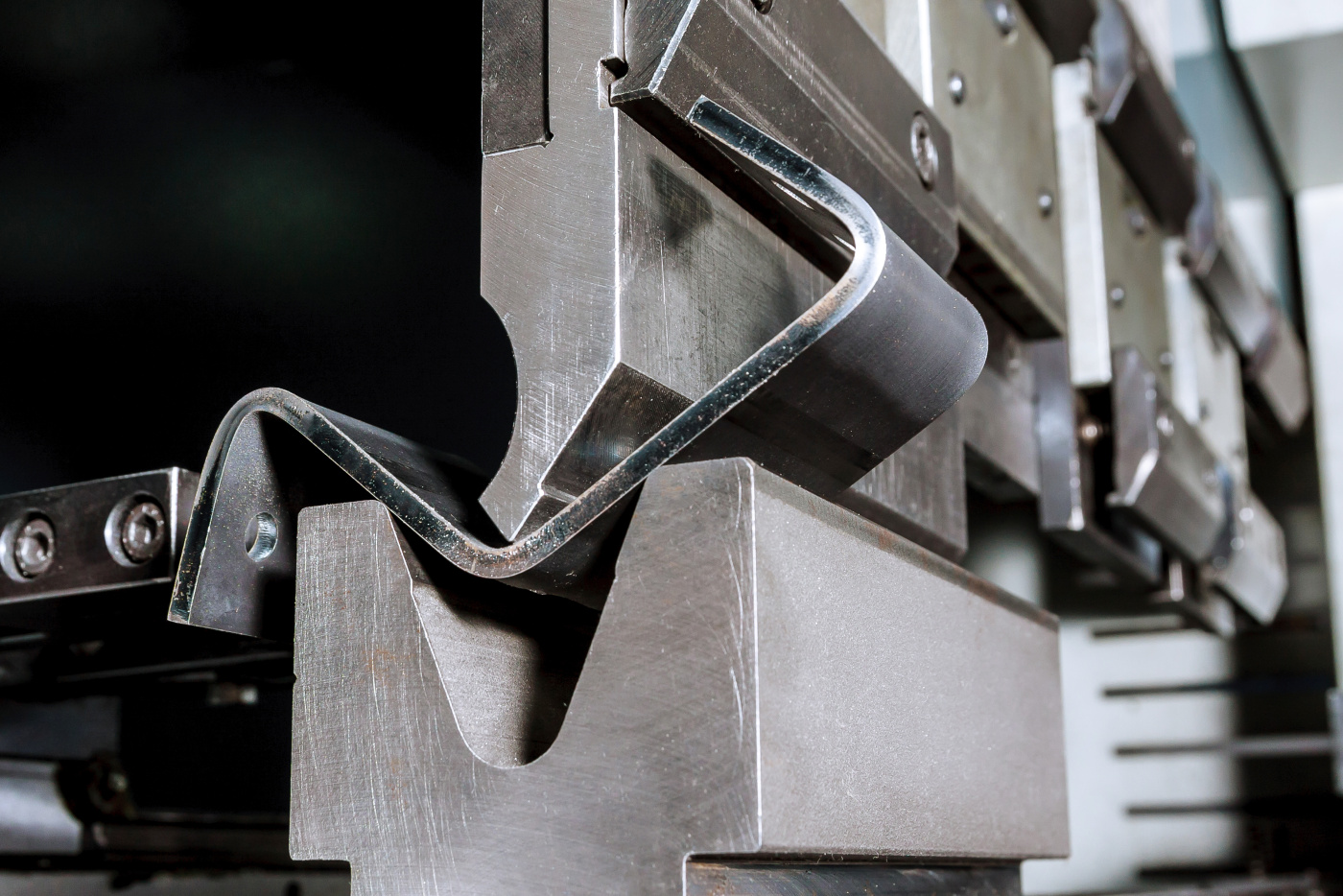

One way to control a hydraulic or forging-press machine is a variable frequency drive based on a frequency converter (VFD). It is used for acceleration, deceleration, and controlling the press motor across the entire speed range.

In CSE, acceleration and deceleration curves, as well as rated operating modes, differ from press equipment, so when selecting a VFD, specific requirements must be considered:

-

Wide speed adjustment range (support for output frequency over 300 Hz).

-

High level of protection for printed circuit boards against fine-dispersion environments.

-

Support for various types of motors.

Presses and crushers are technically complex devices characterized by high starting currents and heavy-duty operation. ONI offers specialized VFDs for such applications: for example, FC-431 and K750.

Their distinctive features:

-

All kinds of expansion boards.

-

Operation with industrial protocols Profibus, EtherCat, Ethernet, CANopen, Modbus RTU/TCP, Profinet.

-

Increased number of inputs and outputs.

-

Support for PID controller and simplified PLC.

-

High overload capabilities — up to 220% for 1 s.

-

Versions with built-in braking module up to 110 kW.

ONI FC-431 frequency converters are designed for general industrial applications

ONI SFC soft starters in press and CSE control

Often, for reliable operation of a press or crushing apparatus, starting and accelerating or decelerating the electric motor within certain time intervals is required. Then the VFD functionality may be excessive, and the optimal solution would be to use a soft starter (SS).

In this case, the soft starter must have expanded capabilities and design features:

-

Various start and stop modes.

-

High overload capacity.

-

Configurable protections.

-

Data transmission via industrial protocols.

-

Presence of a bypass contactor (built-in or external bypass).

For heavy-duty applications, ONI recommends using the SFC SS. This is a technically advanced device with excellent characteristics:

-

Wide rating (up to 800 kW) and support for both 3Ph 380 V and 3Ph 690 V.

-

Increased number of inputs and outputs (5DI, 1AI (Pt100), 2DO, 1AO (4-20 mA), 3RO +1 bypass relay).

-

Support for built-in and external bypass across the entire power range.

-

Remote LCD control panel with real-time clock allows quick SS configuration and remote control of SFC operation up to 10 meters via communication cable.

-

Extended list of configurable protections.

-

Pre-set operating modes (pump, fan, crusher, machine tool, general industrial) ensure quick commissioning;test mode allows debugging SS operation before main start-up.

SFC SS can be used in fire equipment due to a specialized operating mode with built-in protections disabled.

The extended functionality of the ONI SFC SS allows fine-tuning this device for the required technical process and reduces electric motor operating costs.

Example of SFC SS application in presses

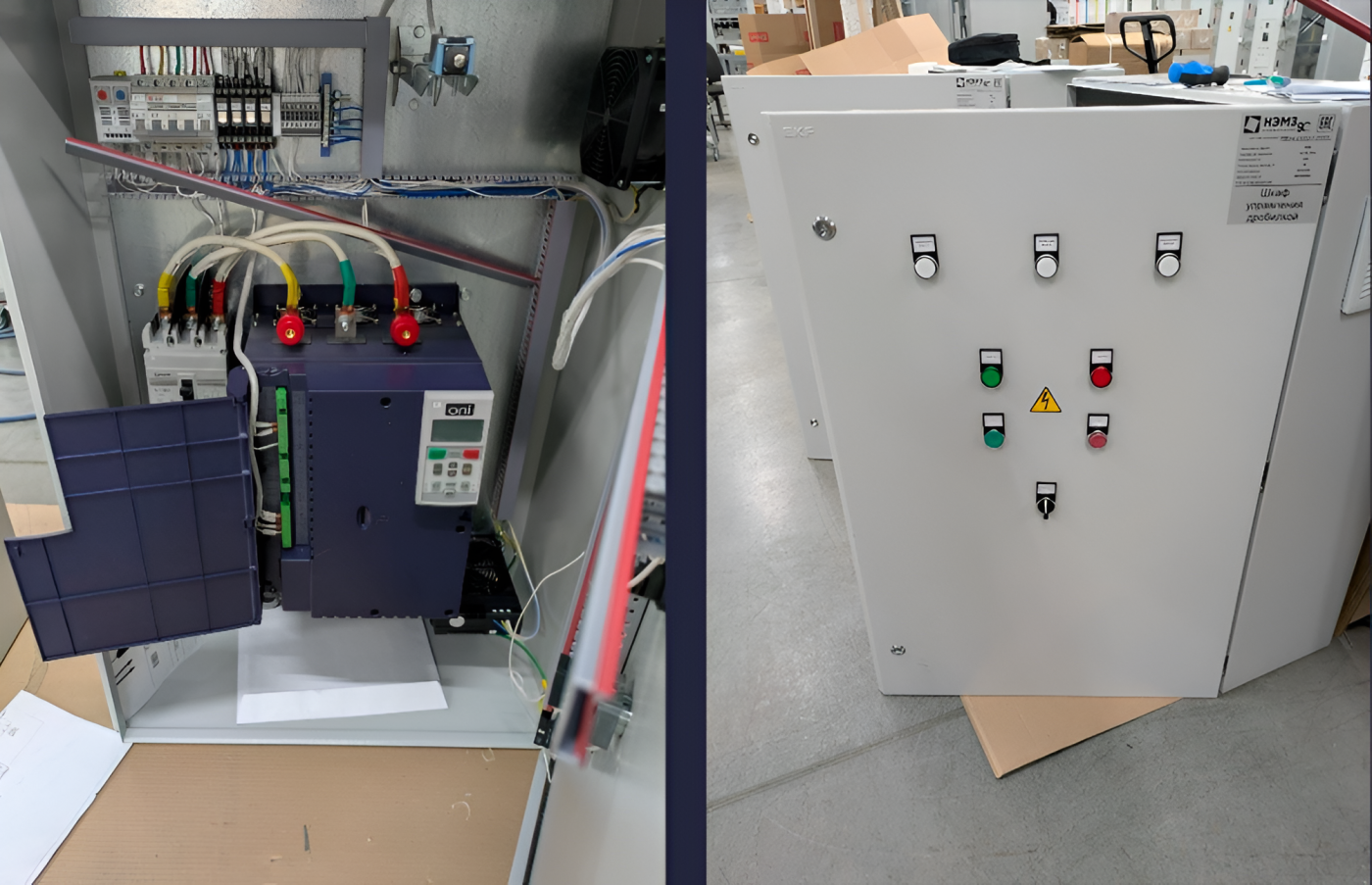

ONI SFC SS were used in the development of a control cabinet (CC) for automating the operation of a vegetable oil production workshop at one of the industrial enterprises in the Russian Federation. The development was carried out by the Novosibirsk Electromechanical Plant (NEMZ). For the solution, SFC SS 3Ph 380V 90kW 180A Ucontrol 110-220V were selected. They control the operation of asynchronous electric motors on mixers and crushers.

Control cabinet based on SFC SS 90 kW for automating the operation of a vegetable oil production workshop

Here are the main advantages of the SFC SS that allow them to work in such harsh conditions as oil production, considering the requirements of the industrial enterprise:

-

high overload capacity (sixfold by starting current)

-

start modes both by voltage and with current limiting or torque support

-

stop mode, including DC injection braking

-

presence of built-in protections against start and operational overloads, overvoltage, overheating of motor and SS.

Oil production is a critical process for the enterprise. Therefore, the SS continuously monitors and transmits data about its own status and motor parameters to the automated control system via the Modbus RTU protocol.

For example, once a minute, data is transmitted about the current protection status, rated and operating currents of the SS, various SS settings during start and stop, number of starts, and actual operating time. All parameters are displayed in text form on the LCD screen. Thanks to the real-time clock, the SS is configured to operate at specific time intervals, including for the purpose of energy saving.

As can be seen from the example, ONI SFC soft starters can solve various industrial tasks and easily cope with work even in harsh conditions and on critical technological processes.

For the entire line of general industrial and industrial VFDs and SSs, ONI supports and develops the assortment of spare parts, tools, and accessories for warranty and post-warranty service. The availability of technical support and service centers, as well as commissioning by IEK GROUP technical specialists, guarantees customers durable and stable operation of ONI equipment.