At its enterprise, IEK GROUP achieved a robotization density indicator exceeding the global average by three times.

According to the International Federation of Robotics (IFR), the average robotization density in the world is 162 units per 10,000 workers. At the "Metal-Plast" production complex of IEK GROUP located in the Tula region, this indicator is 415 machines per 10,000 employees. This is almost three times higher than global averages and comparable to Japan's indicators, where there are 419 machines per 10,000 employees. For comparison: the 2024 rating leaders among countries are South Korea (1,012 robots), Singapore (770), China (470).

"The company's plans are to double the number of robotic systems at 'Metal-Plast' by 2030. Russia's entry into the top 25 leading countries in the world by robotization density indicator by this deadline is one of the national development goals of the country set by the head of state. Focusing on it, IEK GROUP adheres to a strategy of technological leadership, and production robotization allows us to increase work efficiency, guarantee high product quality, and strengthen competitive positions in the market. An important part of this process is also programs for retraining and improving the qualifications of our employees to work with more intelligent equipment," notes Andrey Zabelin, General Director of IEK GROUP.

"Metal-Plast" is the flagship enterprise of IEK GROUP, producing metal enclosures and metal cable trays, PVC cable management systems and accessories for pipes and cable channels, plastic boxes, double-walled HDPE and power connectors, as well as equipment for telecommunications (server cabinets and racks). After 2022, production of IEK TEKFOR plastic boxes was also partially transferred to this site.

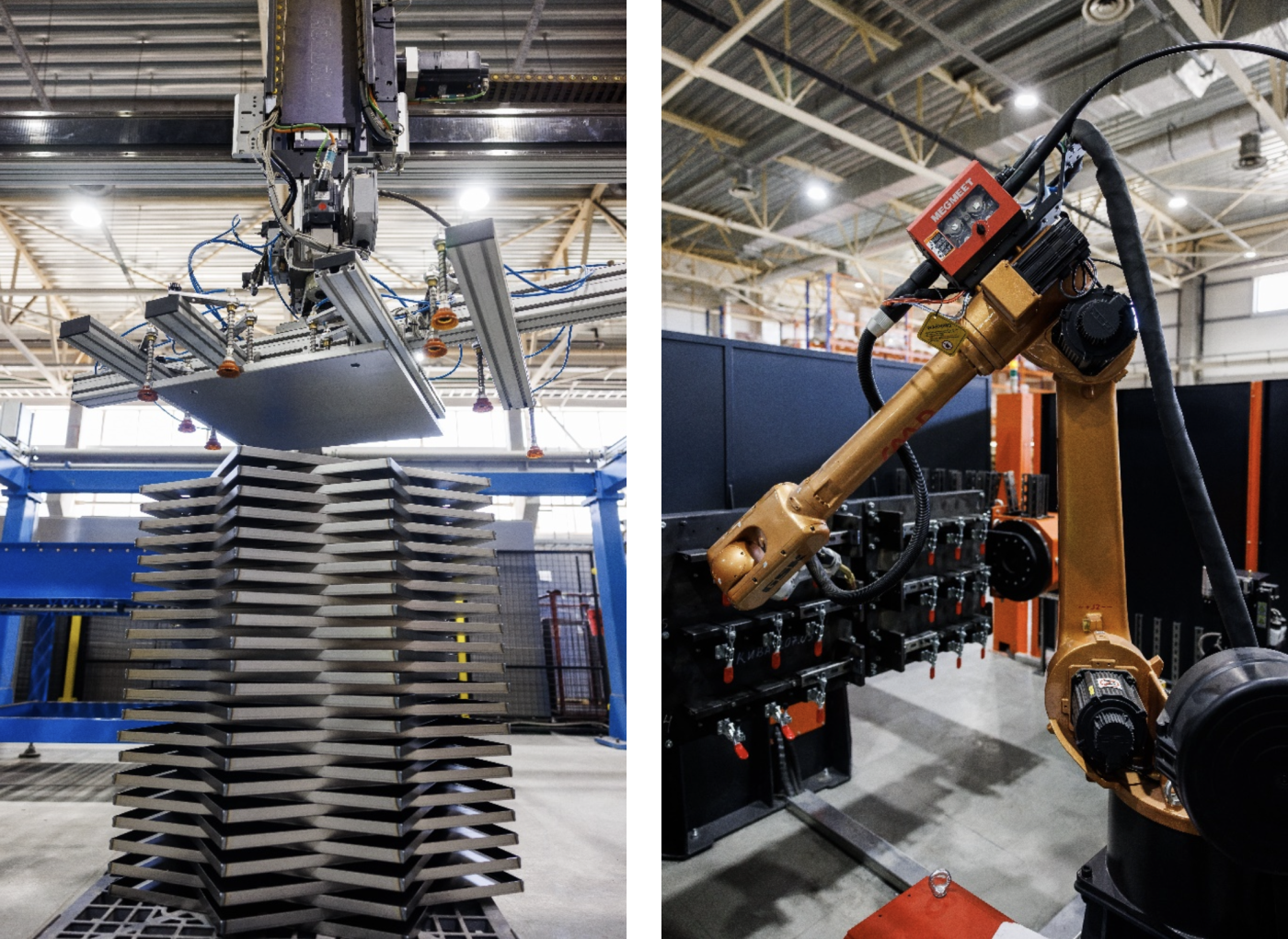

At the enterprise, robots are used for manipulation (lifting objects, moving, positioning, assembling-disassembling parts), laser and arc welding, automatic palletizing of products, unloading goods, transportation, as well as applying two-component polyurethane foam.

"The introduction of robotic complexes, along with AGVs (automatically guided vehicles), artificial intelligence, information systems for production management, and a digital twin is a transition to a qualitatively new level of production. They no longer just help a person but take on the management of complex technological processes. Robots quickly perform routine operations, allowing to increase productivity, and ensure precision, which guarantees high quality and compliance of each product unit with industry standards. Performing dangerous and heavy operations by machines also increases the level of labor safety in production," notes Oleg Ilyin, Deputy General Director of IEK GROUP for Production.

Today, "Metal-Plast" is one of the most robotized productions in the Tula region. Robotization density is the ratio of the number of industrial robots to the number of employees at an enterprise. The indicator allows comparing the level of technological equipment of countries and companies, as well as assessing the development of the economy as a whole.