At the "Oil and Gas—2025" exhibition, IEK GROUP made a loud statement: it was a debut, and it definitely did not go unnoticed! The company presented integrated solutions for energy supply and automation, created considering the needs of the oil and gas industry.

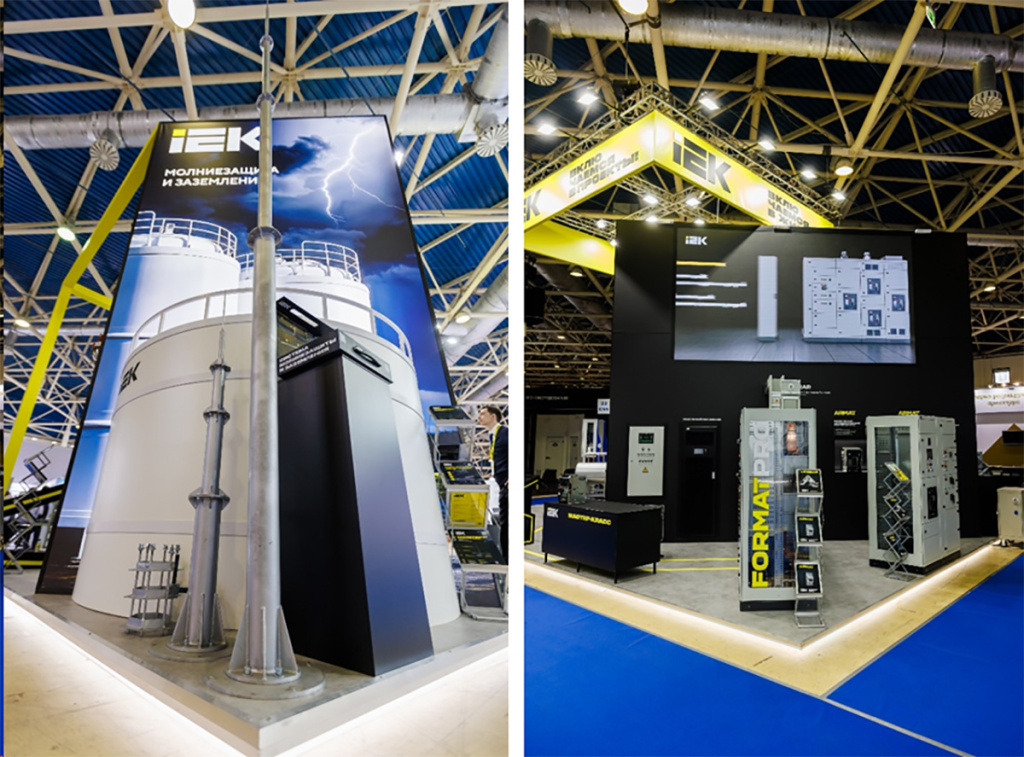

132 sq. meters — and not a centimeter wasted: our stand turned into a true showcase of the technological future. Four key zones — IEK DIGITAL, IEK AUTOMATION, "Solutions for Hazardous Areas", "Russian Production and Localization" — showed that the company knows how to build systems that work as a single whole.

In the IEK DIGITAL zone, guests saw an automated pumping station SHUNS-ONI-MS, fully assembled from IEK GROUP products. Control is based on the PLC ONI TITAN 1070, developed jointly with GC MFMK and included in the Ministry of Industry and Trade register. A digital twin with color-coded operation, a control system on the MasterSCADA and MasterPLC platforms — we showed how smart energy should look.

The IEK AUTOMATION zone presented a three-level ecosystem for industrial facilities based on ONI automation equipment and ITK products for IT communications. The first level (dispatch) includes automated workstations, telecommunication cabinets, industrial computers. The second level (control) consists of controllers, operator panels, frequency converters. For the third level, we offer field equipment: electric motors, relays, sensors, power supplies.

Visitors to the zone for solutions for hazardous area objects were interested in explosion-proof FEREKS luminaires, ARMAFIX terminals, and the intelligent motor control station for a pump jack SU-22. Its advantages include a composite material enclosure, adaptation to aggressive environments, remote monitoring via GSM, and the possibility of dispatch.

At the exhibition, we also demonstrated a solution for lightning protection of oil and gas industry facilities. A free-standing lightning protection mast up to 30 meters high is intended for hazardous areas requiring enhanced protection from lightning strikes, for example, for oil depots.

Traditionally, our flagship switchgear FORMAT PRO, tested for currents up to 4000 A and certified according to GOST IEC 61439, caused a stir. The exposition also included a compact digital switchgear FORMAT PRO based on ARMAT power equipment. The central element of the switchgear was a solution for control and monitoring of the electrical installation, including an ATS based on PLC TITAN 1000.

We also demonstrated a block ATS solution, compatible with the entire line of IEK power and switching equipment. The ATS has self-diagnostic functions and an event log, a graphical display, remote control and management via Modbus RTU protocol is possible. Visitors familiarized themselves with the presented ARMAT power equipment, and in the disassembly zone, where company specialists conducted master classes, they were convinced of the advantages of this line.

In the "Russian Production and Localization" zone, not only the scale of the company's presence in Russia was felt, but also the power of the "Kontaktor" brand. The plant from Ulyanovsk participated in the exhibition for the first time as part of IEK GROUP and presented a retrofit based on the "Proton M" air circuit breaker for modernizing electrical installations. The solution is compatible with any Soviet-era equipment and at the same time equipped with the Modbus protocol, providing the ability to manage power supply parameters using modern systems. This is a kind of bridge between legendary Soviet quality and today's digital standards.

Participation in the "Oil and Gas—2025" exhibition became a manifesto of the comprehensive approach for IEK GROUP: the company does not just supply products but creates technological ecosystems that work in harsh conditions and meet modern requirements for safety, energy efficiency, and digitalization.