IEK has developed a new line of modular equipment called MASTER. How it was created and what distinguishes it from other brand series is explained by Alexey Kosilov, leading designer of the IEK GROUP R&D service.

― IEK's range already includes the ARMAT and KARAT lines, which have proven themselves well among professionals. What prompted the appearance of a new product?

― It complements the existing lines. In terms of characteristics and consumer properties, MASTER IEK is comparable to ARMAT but more affordable. Most importantly, the new series will be manufactured in Russia. For this purpose, a specially designed automated assembly line was set up at the "Kontaktor" plant in Ulyanovsk.

Our main task was to create a high-quality and affordable product that we will produce here, in Russia, using our own facilities.

― And how was this task solved?

― First of all, we sought to create the most ergonomic, easy-to-install and operate product, with above-average characteristics but at an acceptable price. Such wishes were expressed by our customers: we conducted several focus groups with professionals who work with modular equipment daily. It was important for us to release a product that would incorporate their specific wishes.

Therefore, we very carefully chose the design, as well as materials – they had to be of good quality but inexpensive. We found them: the contact tips of MASTER IEK devices are made of a special composite alloy based on silver, and the housing is made of plastic reinforced with fiberglass. It is durable and non-flammable.

— Why was "Kontaktor" chosen for production?

This site is best suited for the production of low-voltage equipment – the plant has been producing it for over 80 years. Over these years, the enterprise has accumulated vast experience, employs highly qualified specialists, and has a unique testing laboratory.

— Tell us how the development of the new line went?

The work took three years. At the first stage, we formed the requirements for the devices: they had to be reliable, safe, functional, and sufficiently simple (without compromising quality). Additionally, we were looking for a design to which additional functions and capabilities could be added.

Then, among the ten best design solutions and technologies, we chose the one that best met our requirements.

Then IEK designers developed the appearance of the future devices.

When the design and appearance were approved, prototypes of the devices were printed on a 3D printer, and we began testing – checking effectiveness and validating the appearance of the future products. In total, there were three iterations of samples at the 3D prototyping stage: if tests showed shortcomings, we created the next prototype, in which they were eliminated.

After that, we made a rough version of the molds and conducted serious tests on samples molded in our plastic, such as tests for ultimate breaking capacity and endurance.

By the way, not every laboratory can conduct a test for ultimate breaking capacity. During it, the test setup is supplied with a current of such magnitude that it could power down a residential block or a small town, especially when testing large-sized molded case or air circuit breakers. IEK GROUP has the capability to test almost any equipment on its own site, in the Electrical Equipment Testing Center of the "Kontaktor" plant. Its generator can deliver up to 135 kA AC and up to 160 kA DC at voltages up to 1.2 kV.

Now we have moved from testing 3D prototypes to testing devices whose plastic parts are molded in the molds. This is a lengthy and multi-stage cycle that will allow us to finally verify that the design of the products is strong, reliable, and safe.

― What are the advantages of MASTER modular equipment?

― It incorporates solutions and capabilities characteristic of equipment in a higher price segment. I will list only some of the technical features.

Shields on the terminals help avoid incorrect wire connection: previously they were only on devices from top European brands' lines. The mechanism with instant contact closing makes circuit breakers and RCBOs safer and increases the contact group's lifespan. Imagine: a circuit breaker trips in an apartment, the housewife goes to turn it on and raises the handle very slowly and carefully. In this case, the contacts will still close almost instantly, eliminating the possibility of them burning.

RCBOs have a color indicator for tripping due to differential current. It is located near one of the handles and turns red if the device tripped due to an earth fault. If due to overcurrent – it remains white. This will help the consumer determine the cause of the device tripping and decide what measures to take accordingly. This feature also exists in the ARMAT series, but the novelty, as we already said, will be available to a wider audience.

Also, the RCBO has a feature that I personally especially like – this is a voltage presence indicator combined with the "test" button. When voltage is applied to the device, the button lights up. And another indicator shows the position of the main contacts, even if the handle is locked: green color – contacts are open, red – closed.

All devices in the new line can be interconnected using FORK or PIN busbars, using the upper or lower terminals. This makes installation more convenient and safer.

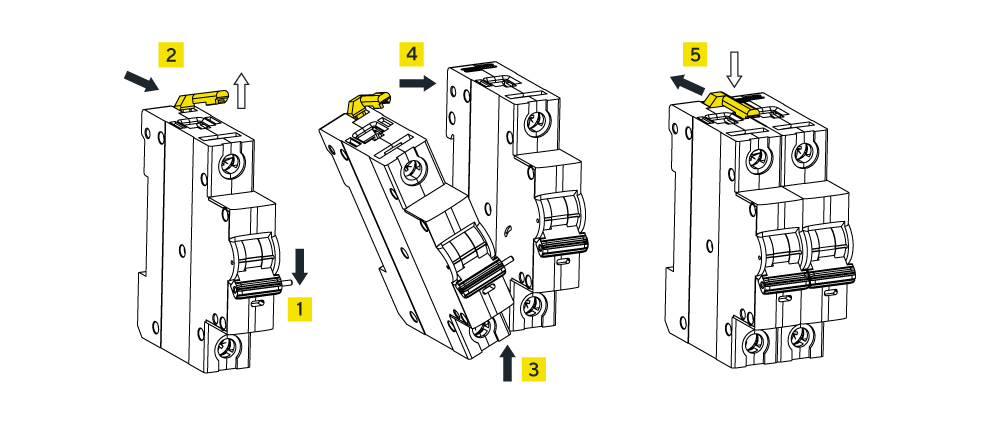

I would separately note the modern FastClip system for attaching additional devices. The spring-loaded latch allows for extremely easy and quick connection and disconnection of devices. This significantly speeds up the connection of additional devices, meaning less time and labor will be spent on mounting an electrical panel.

Simple connection of additional devices in three steps: press the latch, connect the devices, release the latch. Dismantling in reverse order.

― What does the line include and in what industries can it be applied?

― The series includes circuit breakers with breaking capacities of 6000 A and 10000 A, residual current devices (RCDs and RCBOs), and switch-disconnectors. For circuit breakers, RCDs, and RCBOs, additional devices are provided: shunt trips, undervoltage and overvoltage releases, auxiliary contacts for status and tripping. For switch-disconnectors, auxiliary status contacts can be installed.

The line is universal. The devices can be used in infrastructure, commercial construction, and production, but are also perfectly suitable for use in the private sector, medical, and educational institutions.

In general, the MASTER line turned out to be great! We added a whole set of interesting solutions to the devices. This made them safe and reliable, as well as ergonomic and comfortable to work with.